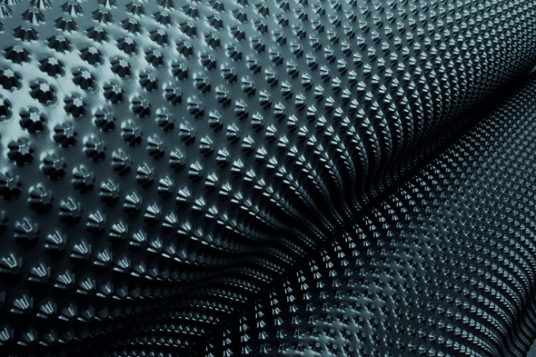

Blister padding with maximum pressure stability

Keep your home dry. A dry and protected cellar is the key to preserving and safeguarding your building’s structural health, protecting against moisture in the masonry, mould and other problems. The first step in this process is to secure effective and permanent protection for your building’s foundations. Dimpled sheets made of special, durable and resilient plastic have proven to be a particularly effective solution for this challenge. Not all dimpled membranes are created equally, however. There are many differences with regards to the strength, stability and the finish of the material. It is all the more important therefore to take a second look and opt for high-quality finishes: your home will thank you long into the future. Our star-shaped dimpled sheeting is perfectly suited to even the most demanding requirements for pressure stability.

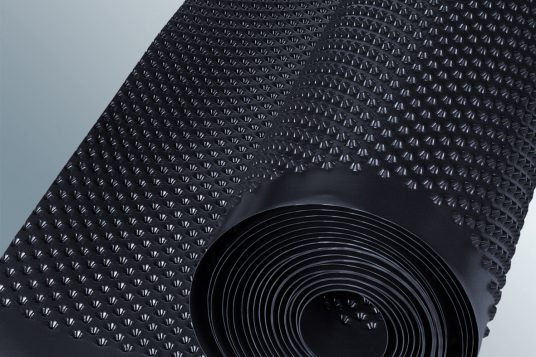

Dimpled membrane, for lasting foundation insulation

When it comes to protecting a building’s foundations, dimpled membrane offers several advantages: It provides superior pressure stability under a wide variety of conditions, protects the foundation walls’ sealing, and keeps the building dry. The material features excellent compressive strength, is shock and break-proof, tear-, root-, and impact-resistant, and elastic. Offering lasting foundation insulation, Gutta dimpled sheet is resistant to abrasion, rot-free, toxicologically harmless, chemical-resistant, and possesses a definite ecological advantage by being drinking water neutral. The material is also highly resistant to fungal and bacterial attacks.

Blister padding for a wide variety of applications

Gutta’s long-lasting blister padding provides effective protection for foundation insulation, for example when sealing with bitumen coatings or sealing slurries. Blister padding serves many other purposes; as a granular subbase or for drainage when roof greening, for example. The superior pressure stability provided by Gutta dimpled sheet derives from the special star shape of the dimples; this design makes the blister padding substantially more pressure-resistant in comparison with conventional dimpled sheeting. The design stiffens the dimples, diverting applied force with greater efficiency. This gives the HDPE plastic a particularly high mechanical resilience. Due to its superior compressive strength, Gutta dimpled sheeting is better able to absorb the pressure that the soil exerts on the sealant when laid vertically. When laid horizontally, the load capacity and resistance of the dimples increases. Gutta dimpled membranes are available in three different versions, each designed according to different requirements.

Laying blister padding to protect masonry

When laying blister padding, you only have to follow a few instructions to ensure its proper, lasting operation. Sealing slurries or bitumen coatings must be dry and pressure-tight. The upper edge of the foundation wall represents the upper fixing point, approx. 10 cm above the sealing coat. The lower fixing point is set directly above the drainage tube. The membrane can be laid directly off the roll. As a general rule, dimpled sheets should be laid out horizontally. Make sure the dimples are facing the wall. The dimpled sheeting is fastened by nailing it at the nail edge.

Drainage with a 20 year warranty

As set out in our warranty, Gutta star-shaped dimpled sheet is guaranteed for a period of 20 years from the date of purchase. Detailed warranty conditions, in particular warranty requirements and limitations, are available as a PDF on our homepage. Upon request, warranty conditions will be sent in text form. Deviations in color and size, etc. within usual tolerances are reserved. Observe local building regulations. Our recommendations do not exempt customers from an obligation to verify the product independently. In case of doubt, we advise expert consultation.