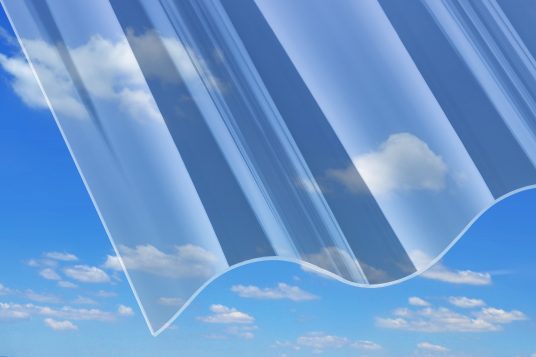

Light panels created at the highest processing quality

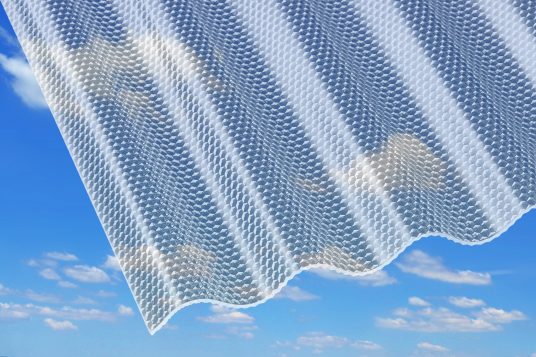

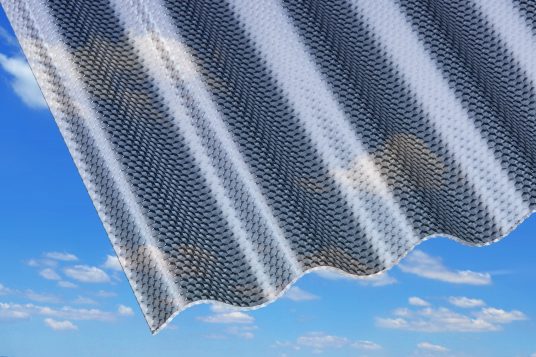

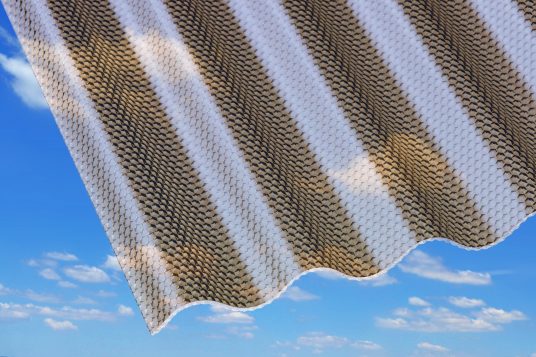

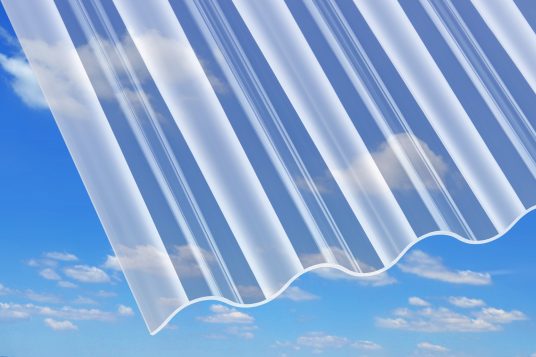

Our 3 mm acrylic corrugated sheets combine numerous advantages, making them an ideal product for roofing and wall coverings for your home. Thanks to the material’s thickness and a special elastomer additive, the panels are hail- and shock-resistant, and exceedingly durable. As such, the corrugated sheets can withstand practically anything that might come along, including rain, hail, storms and/or UV radiation. In addition to their rigidity, our plastic sheets also maintain their permanently brilliant appearance. Yet another advantage: Dirt adheres less to their glossy, non-porous surface than to other materials, leaving the plastic sheets looking fresh and well maintained!

Acrylic profile: A material fit for hundreds of design ideas

Our acrylic profile is available to customers either in smooth or ridged form. This allows you to design your plans individually, and to install roofing or wall coverings that bring aesthetic appeal, solidity and longevity all at once. Furthermore, because the plates are easy to handle and process, you can implement projects around your home creatively and quickly. For experienced DIYers, laying the corrugated sheets will be a simple task.

True versatility, available in high-quality acrylic

Our acrylic corrugated sheets will accompany you around the entire house, wherever you are looking to make embellishments:

- The light panels, of course, make the greatest impression on the terrace, or as balcony roofing.

- Build a modern carport with a translucent roof.

- Beautify your garden with a visually arresting pergola.

- Profile plates can be used to build protective canopies, whether it is at the front or side entrance to your home.

- Set visual accents with special wall coverings, or integrated light strips

- etc.

Always included: Premium quality, backed by a 30 year warranty

No matter how you use our acrylic corrugated sheets to beautify your home, you will rest easy with our 30-year warranty. It is difficult to imagine a more convincing quality guarantee.

Simple, solid, and high-quality: Laying corrugated sheets

Handling our 3 mm acrylic corrugated sheets is easy. To attach, use either acrylic screws, or calottes with stainless steel screws. With plates 4 meters and longer, calottes must be used for installation. With our step-by-step instructions, it is quite simple to lay corrugated sheets:

- Plan for a roof pitch of 10° (minimum 7°).

- First, build a substructure with wooden or metal slats of 40 x 60 mm.

- The distances between the slats should be max. 80 cm for average snow and wind loads. The distance should be reduced accordingly for regions with higher loads!

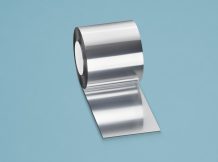

- Subsequently, cover the slats with silver masking tape.

- The next step is to lay the acrylic corrugated sheets. Beginning at the eaves, lay the corrugated sheets towards the roof ridge, always working against the prevailing wind direction. Stagger the sheets in order to avoid corner cuts or quadruple overlaps. Begin the first row with a whole sheet, and the second with a half sheet.

- Continue this process, alternating the sheet length each time.

- Next, pre-drill the plates with a plastic hole cutter.The cross coverage should be one wave, or two waves for a roof pitch below 10°.

- The longitudinal overlap should be min. 15 cm, or 20 cm for a roof pitch below 10°.

- Next, attach the sheet with screws or additional calottes at each third wave crest, and each second crest along the edges and overlap areas. Lay without using spacers.

- Plan on 8 to 10 fixtures per square metre.

- You will subsequently be able to fit moulded parts from our comprehensive range of accessories, as required.