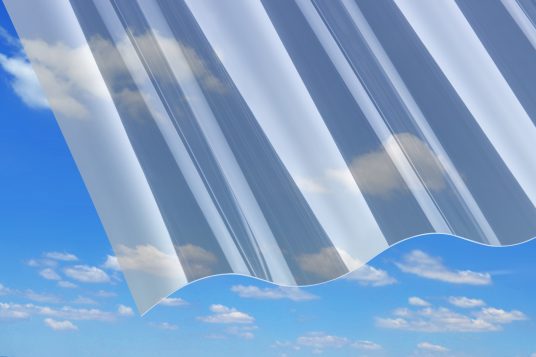

An affordable alternative to many types of roofing

PVC is often a viable roofing solution, especially for light strips, canopies or shelters. In addition to its sturdiness, low weight and excellent price-performance ratio, the particular ease in handling the plastic material makes it a good choice. Here are some basic instructions to keep in mind when roofing:

- Standard roof pitch should be 10°, minimum 7°.

- The substructure can be made with wooden or metal slats of 40 x 60 mm.

- The distances between the slats should be max. 50 cm for average snow and wind loads. The distance should be reduced accordingly for regions with higher loads.

- Cover the cross slats first with silver masking tape.

- Laying should occur against the prevailing direction of the wind, proceeding from the eaves to the roof ridge.

- First, pre-drill the plates with a plastic hole cutter, with holes measuring about 4-5 mm larger than the screw shank.

- The cross coverage should be one wave, or two waves for a roof pitch below 10°.

- Longitudinal overlap should measure 15 cm, or 20 cm for a roof pitch below 10°.

- Attach screws on each third wave crest at the edge of each wave.

- Use spacers!

- Plan on 15 to 20 fixtures per square meter.

- Finally, use fittings as needed.

Warranty and quality for our PVC corrugated sheets

The warranty for our PVC corrugated sheets is regulated by the BGB. Depending on the weather, the transparency and flexibility of the panels may decrease more or less within the warranty period. Deviations in color and size, etc. within usual tolerances are reserved. Observe local building regulations. Our recommendations do not exempt customers from an obligation to verify the product independently. In case of doubt, we advise expert consultation.